You are here

Increasing Lithium Ion Safety with Semiconductors

As the world’s devices get smaller and lighter with increasing power requirements, we need batteries that can provide more power for more time. Modern lithium ion batteries are reaching incredible energy densities enabling devices and vehicles to be more efficient than ever before. All energy storage devices have some risk, however these high energy densities come with increased danger. The dangers of lithium ion batteries have garnered national media attention with the explosions of Samsung smartphones, “hoverboards”, e-cigarettes, and other consumer electronic devices. While manufacturing error contributes to battery failure, many cases of battery explosions are the result of insufficient battery management technology built into the device.

Previous generations of portable devices and vehicles have used nickel cadmium, nickel hydride, or lead acid batteries. These chemistries are inherently less volatile than lithium chemistry packs and do not require constant monitoring. Lithium battery packs are much more finicky, requiring protection from overcharge, over-discharge, temperature, and physical shock. While all batteries can be damaged by these factors, lithium ion batteries become volatile and will overheat, catch fire, and explode.

All devices that have lithium ion batteries should have simple charge regulation; this is required by law for lithium ion batteries on sale in many countries. However, many devices do not have the thermal and over-discharge management for proper safety. Why don’t all devices have these key features? The simple answer is cost. BMS systems are expensive to design and require additional components, which increase the price of each unit.

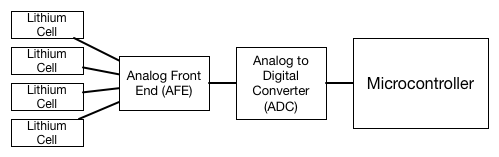

Integrated components designed for battery management greatly reduce design costs and are available on the market; however, they remain prohibitively expensive for many designs. A common component used for battery management is an analog front end (AFE). These chips take care of the level shifting and ground isolation problems faced with measuring the voltages of individual cells; however, the implementation of an AFE chip might increase unit cost by over $10.

Microcontrollers with integrated battery management are yet to be widely available; however, they would fill a design need for low cost battery powered consumer devices, especially for wireless and IOT applications where low power draw is key. ICs designed specifically for creating battery management systems need to come down in cost for more products to use active battery management, which is essential to increase product safety.